| |

|

|

|

| |

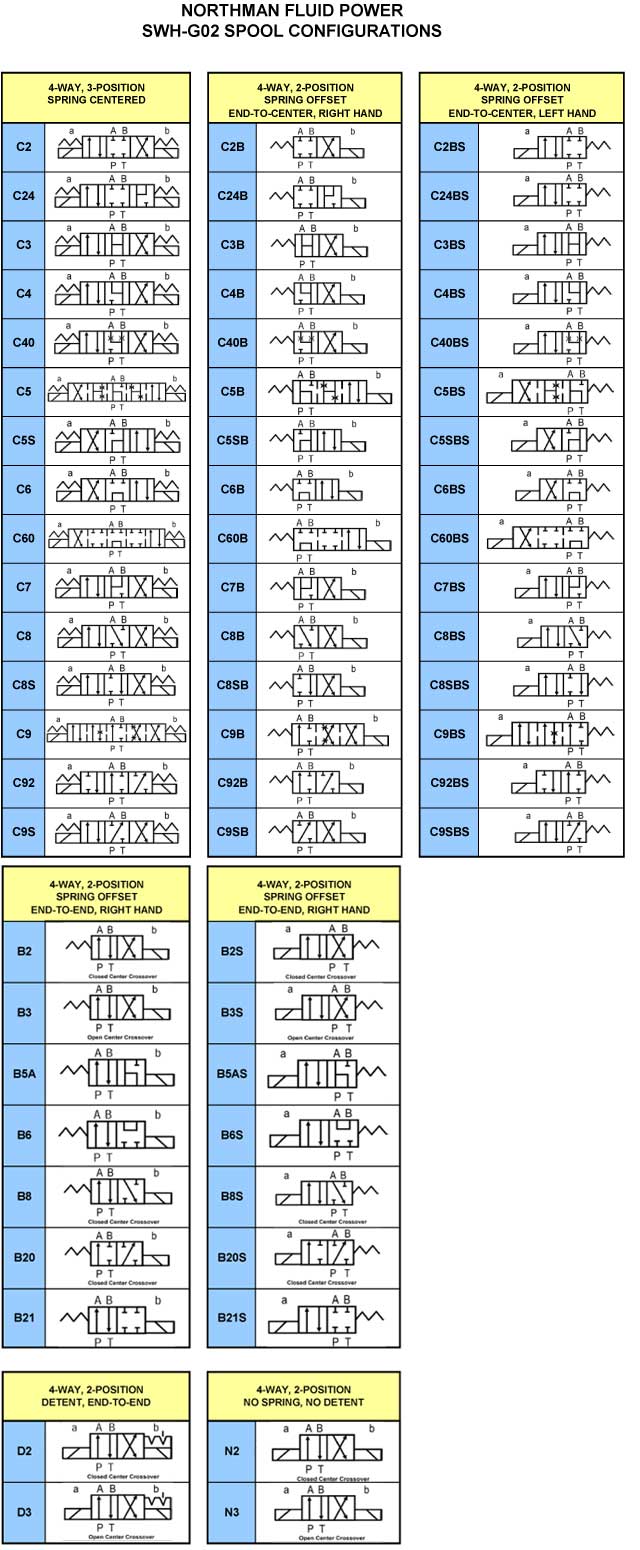

SOLENOID OPERATED DIRECTIONAL VALVE

SWH-G02 SERIES

FEATURES

• Armature operates in oil system. Impact

is cushioned, noise is reduced and solenoid life is increased.

• Wet armature solenoid eliminates pushpin seal, therefore no

seal wear or leakage for longer valve life.

• Molded coils for maximum insulating properties, which is

impervious to moisture and dirt.

• Plug-in solenoid, for ease of maintenance.

• All spools and bodies are interchangeable, simplifying

maintenance.

• Indicating signal lights and bolt kits are standard.

• High pressure, high flow rating, and low-pressure drop.

• Specially designed, balanced spool allows proper shifting

force, for maximum reliability and long life.

• Viton seal kits are available for fire-resistance fluids.

|

|

|

|

|

|

|

|

|

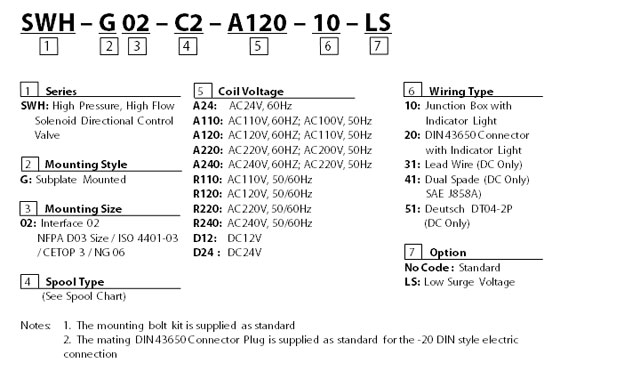

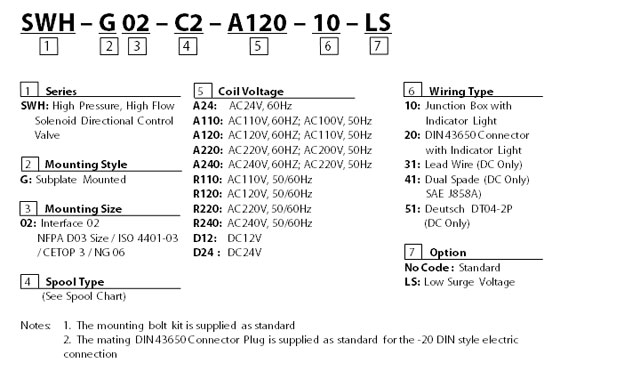

Model Code -

top

|

Specifications -

top

|

Maximum operating pressure |

310 BAR

(4500 PSI) |

| Rated

flow capacity |

63 LPM (16.8 GPM) MAX - Varies by spool type |

| Maximum

tank line back pressure |

138 BAR (2000 PSI) |

| Maximum

frequencies of operation |

300 CPM |

|

Recommended filtration |

25 MICRON |

|

Hydraulic fluids |

Mineral Oil, Viscosity 10 - 400 cST |

|

Temperature range |

-25° C to +90° C (-13° F to +194° F) |

Solenoid Ratings -

top

|

ELECTRIC SOURCE

|

COIL TYPE

|

VOLTAGE

|

CURRENT & POWER

|

|

|

|

|

Hz

|

SOURCE

|

RANGE

|

IN-RUSH

|

HOLDING

|

WATTAGE

|

|

|

RATED

|

(±10%)

|

CURRENT (A)

|

CURRENT (A)

|

|

|

|

|

AC

|

A24

|

60

|

AC24V

|

21.6-26.4

|

6.8

|

1.7

|

|

|

|

(-10 and -20 Options)

|

A110

|

50

|

AC100V

|

90-110

|

1.60

|

0.46

|

|

|

|

|

60

|

AC100V

|

90-110

|

1.40

|

0.32

|

|

|

|

|

AC110V

|

99-121

|

1.50

|

0.39

|

|

|

|

|

A120

|

50

|

AC110V

|

99-121

|

1.30

|

0.38

|

|

|

|

|

60

|

AC120V

|

108-132

|

1.20

|

0.27

|

|

|

|

|

A220

|

50

|

AC200V

|

180-220

|

0.80

|

0.23

|

|

|

|

|

60

|

AC200V

|

180-220

|

0.70

|

0.16

|

|

|

|

|

AC220V

|

198-242

|

0.75

|

0.19

|

|

|

|

|

A240

|

50

|

AC220V

|

198-242

|

0.67

|

0.1 9

|

|

|

|

|

60

|

AC240V

|

216-264

|

0.59

|

0.13

|

|

|

|

R

|

R110

|

50

|

AC100V

|

90-110

|

0.30

|

0.30

|

26

|

|

|

(-10 and -20 Options)

|

60

|

AC110V

|

99-121

|

0.30

|

0.30

|

|

|

|

R220

|

50

|

AC200V

|

180-220

|

0.15

|

0.15

|

|

|

|

60

|

AC220V

|

198-242

|

0.15

|

0.15

|

|

|

|

R240

|

50

|

AC220V

|

180-220

|

0.14

|

0.14

|

|

|

|

60

|

AC240V

|

216-264

|

0.14

|

0.14

|

|

|

DC

|

D12

|

DC 12V

|

10.8-13.2

|

2.20

|

2.20

|

|

|

(-10 and -20 Options)

|

D24

|

DC 24V

|

21.6-26.4

|

1.10

|

1.10

|

|

|

DC

|

D12

|

DC 12V

|

10.8-13.2

|

2.60

|

2.60

|

28.8

|

|

|

(-31 and -41 Options)

|

D24

|

DC 24V

|

21.6-26.4

|

1.30

|

1.30

|

|

TECHNICAL DATA: - top

• Solenoid can be used within -10% to +10% of the

rated voltage of the coil.

• Withstand voltage 1500 v/sec.

• Insulation resistance over 100mQ

• Conforms to rating IP65

• A momentary signal of approx 0.1 second is required for shifting

action.

ACCESSORIES: - top

• Mounting bolt kits are supplied with valve

socket head cap screws

(#10-24UNCx1-3/4"L 4 pcs)

for tightening torque 50-70 kgf-cm (43.3-60.6 lb-in).

• O-Ring AS568-012 4 pcs.

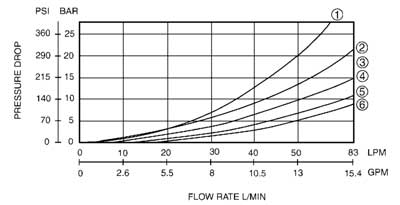

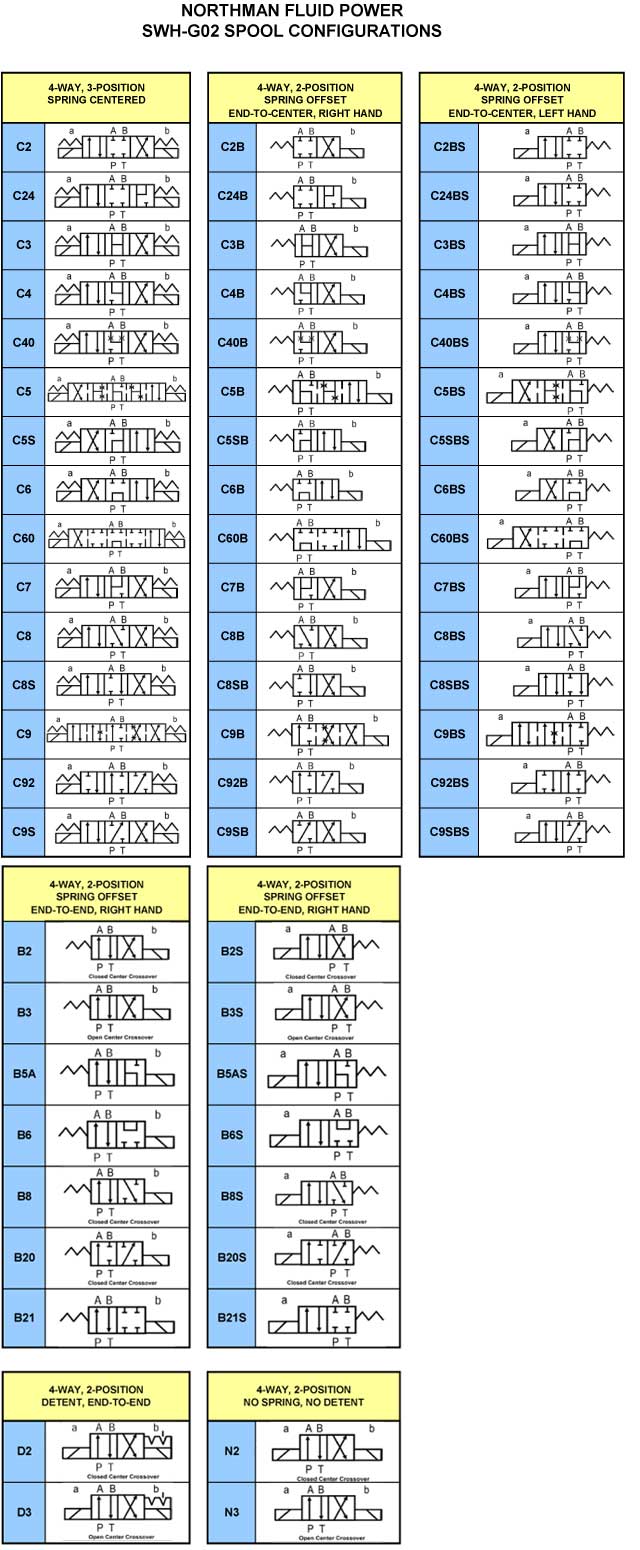

PRESSURE DROP AND PERFORMANCE

CURVES - top

|

SPOOL TYPE NORMAL POSITION |

150 BAR

(2200 PSI) |

207 BAR

(3000 PSI) |

250 BAR

(3675 PSI) |

310 BAR

(4500 PSI) |

50 BAR (735 PSI) |

100 BAR (1470 PSI) |

150 BAR (2200 PSI) |

207 BAR

(3000 PSI) |

250 BAR

(3675 PSI) |

310 BAR

(4500 PSI) |

|

C2 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

|

C3 |

12 (3.2) |

9.(2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9.(2.4) |

7 (1.9) |

7(1.9) |

|

C4 |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

|

C40 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

|

|

12 (3.2) |

9 (2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9 (2.4) |

7 (1.9) |

7(1.9) |

|

C5 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

|

|

12 (3.2) |

9 (2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9 (2.4) |

7 (1.9) |

7(1.9) |

|

C6 |

50 (13.3) |

50 (13.3) |

50 (13.3) |

- |

50 (13.3) |

50 (13.3) |

50 (13.3) |

50 (13.3) |

50 (13.3) |

- |

|

C7 |

40 (10.7) |

40 (10.7) |

40 (10.7) |

- |

40 (10.7) |

40 (10.7) |

40 (10.7) |

40 (10.7) |

40 (10.7) |

- |

|

C8 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

|

|

12 (3.2) |

9 (2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9 (2.4) |

7 (1.9) |

7(1.9) |

|

C9 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

| 12

(3.2) |

9 (2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9 (2.4) |

7 (1.9) |

7(1.9) |

|

B2 |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

40 (10.7) |

40 (10.7) |

18 (4.8) |

14 (3.7) |

10 (2.7) |

10 (2.7) |

|

|

12 (3.2) |

9 (2.4) |

7 (1.9) |

7 (1.9) |

32 (8.5) |

25 (6.7) |

12 (3.2) |

9 (2.4) |

7 (1.9) |

7(1.9) |

|

B3 |

20 (5.3) |

20 (5.3) |

20 (5.3) |

20 (5.3) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

|

B20 |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

63 (16.8) |

37 (9.9) |

30 (8.0) |

28 (7.5) |

|

|

45 (12.0) |

45 (12.0) |

45 (12.0) |

45 (12.0) |

45 (12.0) |

45 (12.0) |

|

D2 |

25 (6.7) |

20 (5.3) |

18 (4.8) |

15 (4) |

63 (16.8) |

50 (13.3) |

45 (12.0) |

40 (10.7) |

32 (8.5) |

25 (6.7) |

|

|

45 (12.0) |

30 (8.0) |

28 (7.5) |

25 (6.7) |

22 (5.9) |

18 (4.8) |

|

D3 |

25 (6.7) |

21 (5.6) |

16 (4.3) |

13 (3.5) |

40 (10.7) |

30 (8.0) |

25 (6.7) |

21 (5.6) |

16 (4.3) |

13 (3.5) |

|

|

25 (6.7) |

21 (5.6) |

16 (4.3) |

13 (3.5) |

40 (10.7) |

30 (8.0) |

25 (6.7) |

21 (5.6) |

16 (4.3) |

13 (3.5) |

NOTE:

1. The figures in the square show the flow under saturated temperature

and 90% rated voltage.

2. The upper number in table describes the maximum flow under DC and R.

the lower number in table describes the maximum flow under AC.

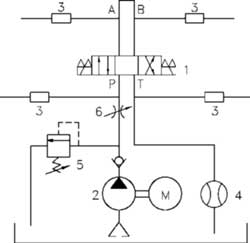

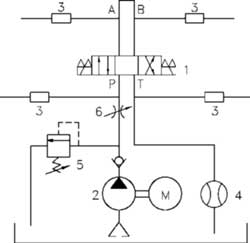

TEST SYSTEMS-

top

1. Testing Valve

2. Pump

3. Pressure Sensor

4. Flow Sensor

5. Relief Valve

6. Throttle Valve

TEST CONDITIONS

Pressure: 138 BAR (2000PSI)

Flow Rate: 30 LPM(8 GPM)

Viscosity: 35 cSt(175 SSU)

TEST CIRCUIT

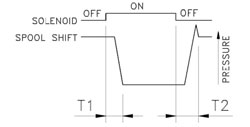

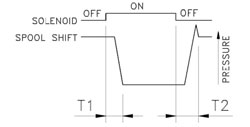

|

MODEL |

CHANGE OVER TIME (sec) |

| T1 |

T2 |

|

SWH-G02-AC SERIES |

0.01-0.04 |

0.02-0.04 |

|

SWH-G02-DC SERIES |

0.02-0.06 |

0.02-0.04 |

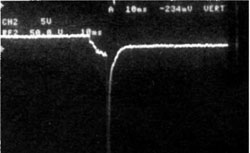

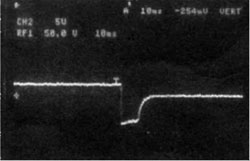

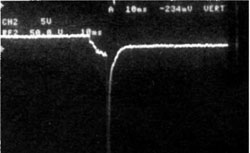

OPTION LS-

top

ELECTRICAL SURGE CONTROL MODEL SWH - G02 - *** - D ** - ** - LS

FEATURES

• Suppresses the surge voltage.

• Eliminates sparks between relay contacts.

• Extends the life of the relay contact.

EFFECTS

• Improves the reliability of the control relay.

• Extends the life of conventional relays.

• Can be operated with a miniature relay.

• The RAC rectifier built-in DC model eliminates sparks at the control

relay contact. It can be directly operated with a PLC (programmable

logic controller).

| Electrical surge waveform standard DC

solenoid |

Electrical surge control DC solenoid |

|

|

|

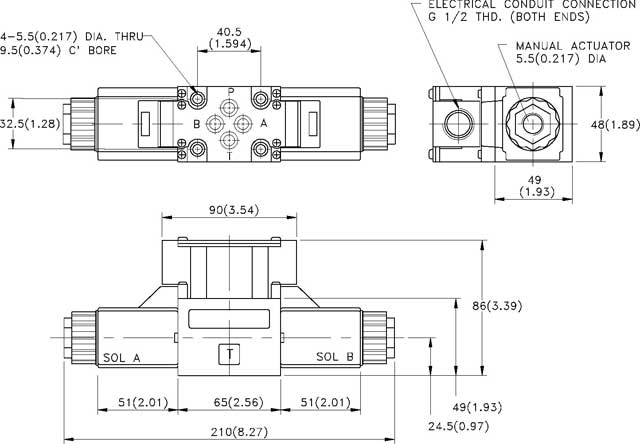

Dimensions -

top

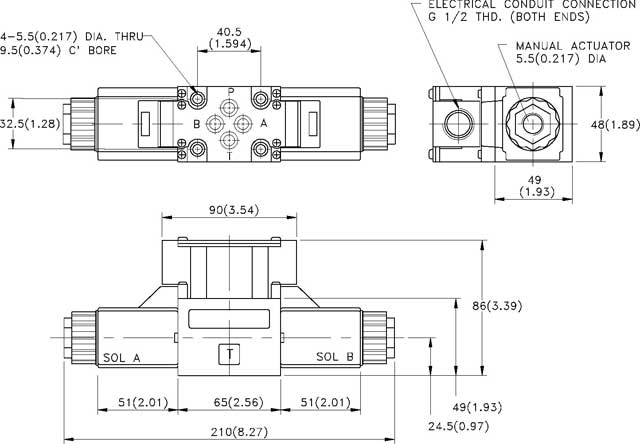

SWH - G02 - C ** - **** - 10 - **

with AC/DC/RF solenoids

|

MOUNTING

SURFACE: ISO 4401-AB-03-4-A

UNIT: mm( inch) WEIGHT: 2.0 kgs (4.4 lbs) |

|

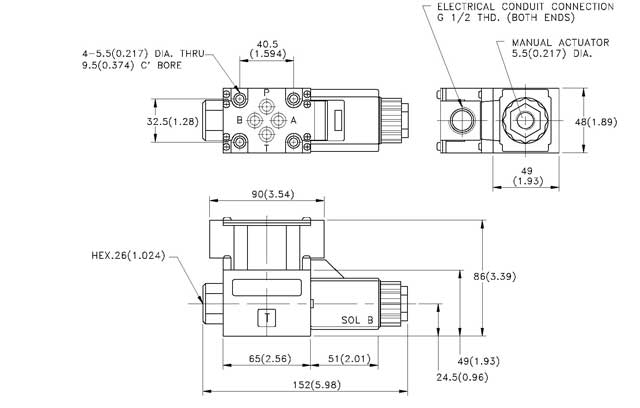

Dimensions -

top

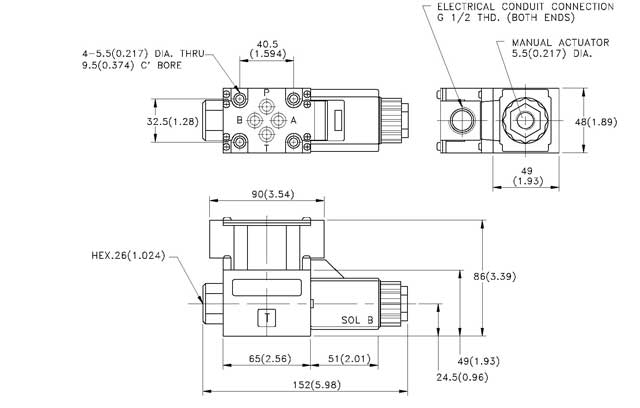

SWH - G02 - B ** - **** - 10 - **

with AC/DC/RF solenoids

|

MOUNTING

SURFACE: ISO 4401-AB-03-4-A

UNIT: mm( inch) WEIGHT: 2.0 kgs (4.4 lbs) |

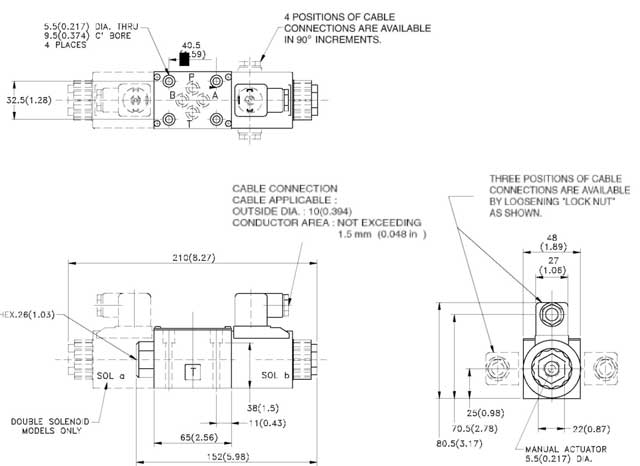

Dimensions -

top

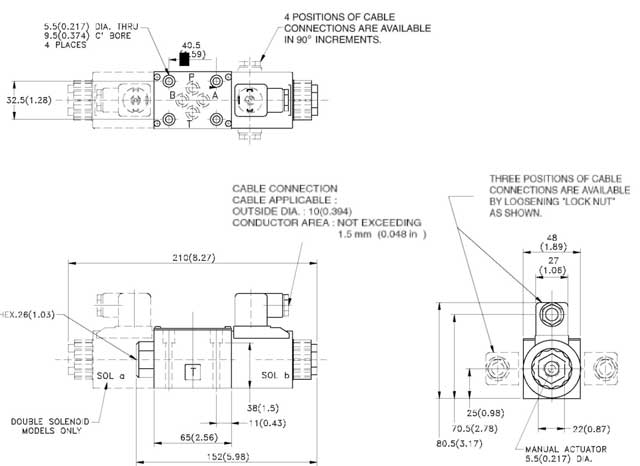

SWH - G02 - *** - **** - 20 - **

with AC/DC/RF solenoids

|

MOUNTING

SURFACE: ISO 4401-AB-03-4-A

UNIT: mm( inch) |

Model and Weight -

top

|

MODEL |

WEIGHT |

MODEL |

WEIGHT |

| kg(lb) |

kg(lb) |

| SWH-G02-C

**-A***-10-** |

1.9(4.18) |

SWH-G02-C -A ***-20- ** |

1.9(4.18) |

| SWH-G02-B **-

A***-10-** |

1.6(3.52) |

SWH-G02-B- A***-20-** |

1.5(3.3) |

| SWH-G02-C**-

D/R***-10-** |

2.0(4.4) |

SWH-G02-C - D/R ***20-** |

2.0(4.4) |

| SWH-G02-B**-

D/R**-10-** |

1.6(3.52) |

SWH-G02-B - D/R ***-20- ** |

1.6(3.52) |

| SWH-G02-D **-

A ***-10-** |

1.9(4.18) |

SWH-G02-D- A ***-20- ** |

1.9(4.18) |

|

SWH-G02-D**-D/R ***-10-** |

1.9(4.18) |

SWH-G02-D - D/R *** -20-** |

1.9(4.18) |

|

![]()

![]()